2022 December 2nd Week WSW Technical Knowledge: High speed light load vacuum pump needs a new solution Bearing solutions for vacuum pumps and compressors

SKF introduced a single row angular contact ball bearing that improved and expanded the Explorer series. This series of products are used in screw compressors and pump equipment, including industrial screw vacuum pumps. The bearing can help to increase the specific power of the equipment and enable the equipment to operate at higher speeds and lower friction, thus improving the performance and efficiency of the equipment. In addition, this series of bearings can be supplied globally, with cost competitive advantages and service advantages.

Compressed air is often referred to as the "fourth power source". For most manufacturing plants, the reliability and efficient performance of the compressor system are critical. Twin screw compressor is a common type of compressor in many industrial equipment. In addition to compressed air, more and more modern production processes also require varying degrees of vacuum environment. Vacuum pumps are very similar to air compressors and are commonly used in many industries, including food, beverage and packaging industries, optical, electronic and semiconductor industries, as well as chemical, pharmaceutical and glass industries. In these industries, vacuum pumps are used in industrial coating processes such as chemical vapor deposition and physical vapor deposition. In addition, vacuum pumps are even used in large-scale scientific laboratories such as gravity wave detection.

Typical compressor or vacuum pump based on twin-screw technology

Like the twin screw compressor, the screw vacuum pump uses two screw shafts that mesh with each other and rotate in opposite directions to suck the gas into the cavity between the screws, and then it is compressed and delivered to the exhaust end; At the inlet side, after the gas is pumped away, the pressure drops to the set vacuum level. The bearing supporting the screw rotor is a key component of the screw vacuum pump: it not only bears the load generated by the gas pressure, but also ensures the accurate positioning of the rotor in the radial and axial directions, which is a key indicator to measure the efficiency of the screw machine.

In the future, the compressor and pump market expects a higher speed, a more compact design, and the use of reverse support bearings with more accurate axial positioning and more stable performance. The so-called reverse support bearing is used to bear the reverse load. By controlling the axial clearance of the bearing configuration, the clearance between the two shafts and between the bearing and the casing can be controlled. This bearing will be affected by both high speed and low load. For the screw vacuum pump, the three characteristics of speed, efficiency (achieved by good sealing of the gap) and low heat are crucial.

Screw compressor with 25°angular contact ball bearing

Design improvement

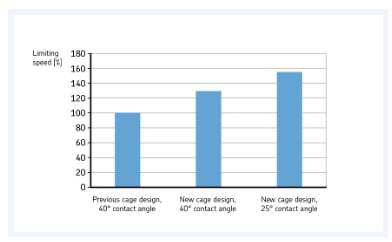

In order to meet the above new requirements, SKF has made many improvements to the bearing design and developed a new product series to ensure that SKF Explorer single row angular contact bearings can meet the current and future performance requirements. The first innovation is a new type of cage, whose geometric shape has been significantly improved, and a new type of brass material has been used, which can reduce friction and improve running speed.

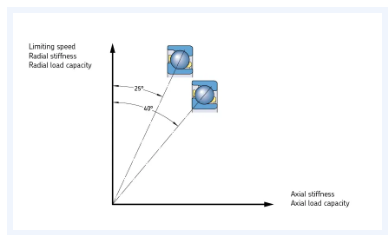

In addition, SKF standard angular contact ball bearing series has added new products with 25°contact angle. Both 25°and 40°contact angle bearings use improved new cages. Compared with the bearing with 40°contact angle, the bearing with 25°smaller contact angle can operate at a higher speed, and has better performance as a reverse support bearing under light load. In addition, the 25° contact angle bearing has a higher radial bearing capacity than the 40°contact angle bearing, which can highlight its advantages in applications mainly bearing radial loads, and help to reduce the size of equipment. As a standard design product, 25°contact angle bearing can also ensure global supply and short delivery time.

Another key advantage of the 25°contact angle bearing series is the universal pairing with other 25° and 40°contact angle bearings, which means they can be assembled together to form a pair configuration or a triple configuration without any clearance measurement.

25°contact angle bearing is a new product of standard angular contact ball bearing series

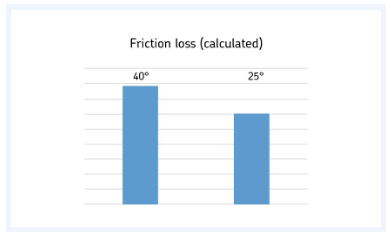

Comparison of calculation results of bearings with 25 ° contact angle and 40 ° contact angle

Comparison of the Limit Speed of Single Row Angular Contact Ball Bearings with Machined Brass Cages

With machined brass retention? Bearing Temperature Comparison of Single row Angular Contact Ball Bearing with Grease Lubrication of

Design Example

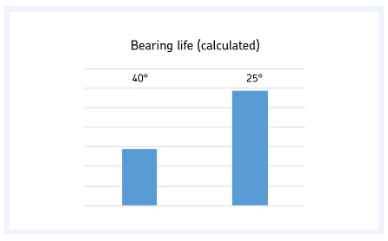

A customer sought technical support from SKF when verifying the design scheme of its new generation screw vacuum pump. SKF used the 3D simulation software SimPro to conduct a comprehensive analysis of the bearing system in the design scheme. The analysis results show that there are some performance risks in the use of 40 ° angular contact ball bearings, such as shorter design service life, greater contact angle variation and higher friction loss. In addition, at very high speed, the centrifugal force acting on the steel ball needs to be considered. In this case, smaller contact angle has better kinematics characteristics.

Using SimPro, a SKF simulation tool, the nonlinear dynamics of the bearing in the screw vacuum pump equipment was comprehensively analyzed

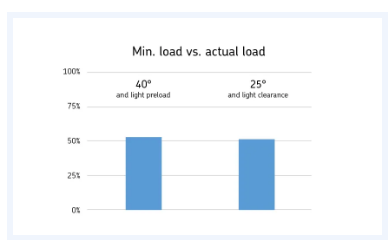

Compared with screw compressors of similar size, the customer's vacuum pump has a higher speed and less axial load. The analysis results show that the ideal design scheme is to adopt double bearing configuration, including the new SKF Explorer bearing with 25°contact angle and small clearance. The calculation results in the figure below clearly show the performance differences of different bearings in terms of calculating life and reducing power consumption.

Advantages of the latest improvements

The newly improved SKF Explorer single row angular contact ball bearing series can bring customers a series of benefits:? Products can be supplied from stock with higher cost efficiency. In terms of performance, the 25°angular contact ball bearing series can operate at a higher speed; It has better performance as a reverse support bearing under light load conditions; Higher radial bearing capacity can reduce equipment size; Improved new machined brass cages help ensure quiet operation and reduce friction losses. The new series includes three clearances and three preload levels, providing great design flexibility. In addition, 40°and 25°contact angle bearings can be matched universally, so logistics, inventory management and equipment assembly are clear at a glance. SKF's global business coverage and timely delivery capabilities make the above advantages even more prominent.

More about WSW Tapered Roller Bearings:

WSW tapered roller bearing belongs to separate bearing, and the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows of rollers installed. Single row tapered roller bearings can withstand radial load and axial load in a single direction. When the bearing bears radial load, an axial component will be generated, so another bearing that can bear the axial force in the opposite direction is needed to balance.

Features and benefits of WBM tapered rollers:

1) Low friction, noise, and vibration

2) Long service life

3) Enhanced operational reliability even under difficult conditions

4) Running-in period with reduced temperature peaks

5)Separable and interchangeable components help to facilitate mounting, dismounting and maintenance

Wafangdian Guangda Bearing Company is a comprehensive enterprise, which is a collection of bearing D&R, production and selling, and has passed ISO9001-2000 quality management system certification. Now it can produce various types of bearings, over 200 series and 5,000 designations or so. For example, deep groove ball bearings, spherical ball bearings, cylindrical roller bearings, self alining roller bearings, angular contact ball bearings, tapered roller bearings, thrust ball bearings, thrust roller bearings, spherical plain bearings, car hub bearings, slewing bearings and British series bearings and so on. It can also design and produce various types of non-standard bearings according to customers’ different requirement. Products are widely used in metallurgy, mining, petroleum, chemical industry, machinery, vehicles, papermaking, cement industries etc, and exported to Europ, USA and South Asia market and gained cuctomers’ recognition at home and abroad.