2022 November the Second Week WSW Technical Knowledge: Split Cylindrical Roller Bearing for Kiln Car

H标题:Structural form and split principle the usage of split type cylindrical roller bearing for kiln car.

In recent years, the fire resistance, electric porcelain, ceramics, fire resistance and other industries in China have developed rapidly. Tunnel kiln cars are the key equipment for loading blanks into kilns in the above industries. Therefore, the reasonable selection of kiln car bearings is more important. It has the characteristics of large load, slow running speed, high working environment temperature, large temperature difference, more dust, long continuous working time, etc. Ordinary bearings are selected, which cannot withstand the high temperature baking. In addition, the carbon formation of lubricating grease will cause heavy rotation or seizure of the bearing. If the kiln car fails and cannot enter and exit the closed tunnel on time, the baking quality of the blank will be directly affected, resulting in raw burning, over burning and cracking. It is urgent for our bearing manufacturers to solve the problem of reliable operation of kiln car bearings under high temperature and easy maintenance and replacement.

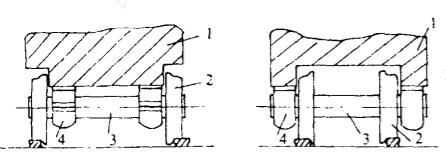

There are basically two types of kiln car structures, as shown in Figure 1, with each half of the market share. The support bearing of the kiln car in the right figure is outside the wheel, which is convenient for disassembly and maintenance. However, the kiln car with the structure shown in the left figure is supported on the inner side of the bearing. It uses ordinary bearings. When disassembling, repairing and replacing the bearings, it is necessary to return the wheels. As we know, the kiln wheel and shaft are assembled by hot pressing on pressure equipment of a certain tonnage, so it is very difficult to disassemble and assemble them. In order to solve this problem, we specially developed split cylindrical roller bearings for kiln cars.

1. Vehicle body 2. Wheel 3. Axle 4. Bearing seat

Fig. 1 Position of kiln car wheel and bearing

1. Structural form and split principle

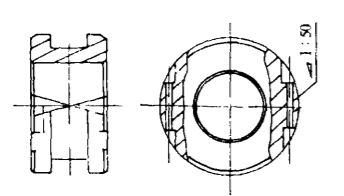

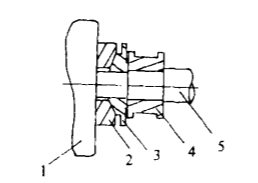

The inner and outer rings and cage of the round roller bearing are divided into two parts according to the radial direction, which is an ideal bearing type for radial installation of difficult parts. It can be conveniently installed on any part. The internal and external rings of the split cylindrical roller bearing are divided mechanically. The split process can be carried out after hard grinding. Before finish machining, the split inner ring needs to be positioned with a taper pin to restore the two halves of the inner ring to the original position of the integral inner ring. After fastening with two socket head cap screws, enter the finishing grinding sequence to make the fit tolerance between the inner ring and the shaft meet the accuracy required by the design. As shown in Figure 2. The axial positioning of the inner ring depends on two separate low-carbon steel inner gland and clamping flap, and the inner gland and clamping flap are locked by the inclined plane, so the axial positioning is more reliable, as shown in Figure 3. After the split outer ring is positioned and bonded with a holding adhesive, it is clamped with a fixture and then finished to make it meet the design accuracy. The axial position is positioned against the outer gland and the end face of the bearing seat. No cage and full roller arrangement are adopted, which can save one cage, increase the number of rollers and improve the bearing capacity.

Fig. 2 Structure of bearing inner race

1. Wheel 2. Clamping disc 3. Inner gland 4. Bearing inner race 5. Shaft

Fig. 3 Axial Positioning Diagram of Bearing Inner Race

Since the inner and outer rings are divided by mechanical processing, there are joints at the dividing line. In order to improve or reduce the impact and vibration when the roller crosses the dividing line area, the dividing line and the axis line may be at a certain angle.

2. Usage

In order to further verify the application effect of the split cylindrical roller bearing for kiln car developed by our factory, the installation test was carried out in the nearest refractory plant of Benxi Iron and Steel Co. The use of bearings is described and analyzed below. The firing process of refractory bricks is as follows:

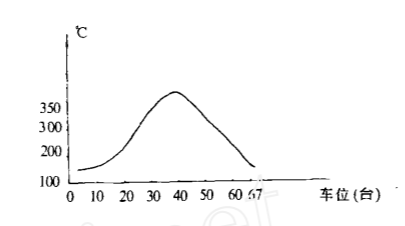

The car in front of the kiln will transport the brick kiln car to the place parallel to the tunnel kiln track, and then the car-jacking machine will drive it into the tunnel kiln. After drying, preheating, roasting and cooling, the car at the end of the kiln will carry it to the finished product warehouse. See Fig. 4 for the change of temperature under the kiln with the kiln car parking space. The working environment of the honey truck is relatively poor. Each kiln truck is equipped with four sets of bearings. The bearing operation mode is that the inner ring rotates with the shaft.

During the working process of kiln cars, several dozen kiln cars are pulled by the top of the screw jack car or the steel wire rope winding, and move forward in sequence in high temperature. As the temperature of the firing zone in the kiln is as high as 1300 ℃, the wheels, bearing pedestals and bearings of the kiln car are still affected by radiant heat and heat conduction, and the maximum temperature can reach about 250 ℃, despite the use of thermal insulation measures such as sand sealing under the furnace.

One continuous working time of the kiln car in the furnace is about 58 hours. The dead weight of the kiln car is about 3 tons, including the maximum brick load of the masonry surface of about 45 tons. Thus, the load of each set of bearings in the kiln car is nearly 2 tons. The bearing is worn during rotation, so it is necessary to add appropriate high-temperature grease to reduce friction resistance and prevent grease carbonization.

Due to the above reasons, the 3616 bearing originally used in the kiln car often gets stuck or rotates heavily, making the wheels crawl on the track under the action of tension or thrust. As a result, the related equipment and spare parts were damaged very quickly, which seriously affected the firing quality of refractory bricks. In order to further verify the use effect of the split cylindrical roller bearing for 802000 series kiln cars. At the beginning of 1992, the kiln car bearing and the high-temperature lubricating grease developed by our factory were used in the refractory materials factory of Benxi Iron and Steel Co., Ltd. for the field installation test of kiln car bearing production, and the assembly was carried out in strict accordance with the assembly method. After more than a year of trial operation, the kiln car bearing was praised by the field production workers, engineering technicians, and maintenance section. It is generally believed that the special kiln car bearing produced by our factory is longer in service life, easier to promote, and better in energy saving than the 3616 bearing. It will bring greater economic benefits to users, especially the split structure of kiln car bearing, which is convenient for maintenance and replacement. As the provincial machinery committee stated in the appraisal conclusion of the product, "The product is novel in design, reasonable in structure, advanced in technology, and unique in technology. The product has reached the domestic leading level and filled the domestic gap, with remarkable economic benefits".

Fig. 4 Temperature Change under Kiln

More about WSW Deep Groove Ball Bearings:

WSW excellent quality deep groove ball bearing with reasonable price for customers all over the world and can produce various types of bearings,over 200 series and 5000 specifications or so.

Deep groove ball bearings are the most widely used bearing type and are particularly versatile. They have low friction and are optimized for low noise and low vibration which enables high rotational speeds. They accommodate radial and axial loads in both directions, are easy to mount, and require less maintenance than other bearing types.

We promise that WSW only provides excellent quality products with the best price and the most professional service! We sincerely invite all of you to cooperate with us.