WSW Technology Knowledge: Development and Trend of stamped Cage Structure of Cylindrical Roller Bearing

Characteristics, performance and evolution of stamped cage structure of various cylindrical roller bearings

Abstract: The structure and characteristics are introduced for stamped cages of cylindrical roller bearings. The characteristics performances and evolution are analyzed for various types of the stamped cages. The reasons for slow development and trend of domestic stamped cages of cylindrical roller bearings are summarized.

Key words: cylindrical roller bearing; cage; structural improvement; development tendency

Cylindrical roller bearings (or single row cylindrical roller bearings, short cylindrical roller bearings) are in line contact with the raceway and have higher bearing capacity than ball bearings. They are widely used in machine tool spindles, transportation machinery, reducers, compressors and other fields. Bearing types include NU (outer ring double retaining edge, outer ring without retaining edge), N (inner ring double retaining edge, outer ring without retaining edge), NJ (outer ring double retaining edge, inner ring single retaining edge), NF (inner ring double retaining edge, outer ring single retaining edge), NUP (outer ring double retaining edge, inner ring with flat retaining ring), NJ + HJ (outer ring double retaining edge, inner ring with L-shaped inclined retaining ring), LSL (with disc cage), ZSL (with spacer cage) and full roller, without outer ring No inner ring and other structures. In order to meet the application requirements of cylindrical roller bearings with different structural types and materials, the structural types and materials of cages have also changed greatly. The research progress of cages ensures the development and progress of cylindrical roller bearing technology.

1. Structure and characteristics of stamped cage

The stamped cages of cylindrical roller bearings include B-shaped, cylindrical, grooved, combined cages, M-shaped and M-shaped band end locks, cylindrical band end locks and other structural improved cages.

The biggest characteristics of stamped cage are: high strength, longer and larger diameter rollers can be used, and large bearing capacity; Light weight and high limit speed; When the technology and equipment are mature, the processing efficiency is high and the cost is lower than that of copper cage.

The foreign materials of cylindrical roller bearing stamped cage are generally cold-rolled steel, such as DC01, SPCC, etc. in China, high-quality carbon structural steel sheet, such as 08F, 08, 10F, 10 steel, etc., can meet the mechanical and process properties specified in GB / T 28268-2012 Technical Conditions for Rolling Bearing Stamped Cage, and a few adopt 08AL, 10AL, stainless steel, brass, spring steel, etc.

2. Structural development of stamped cage

2.1 B-shaped cage

The cylindrical roller bearing first adopts the B-shaped cage, initially adopts the external bending claw, and gradually transforms the internal bending claw to lock the roller by the bending claw on the beam. The cage has relatively simple structure and convenient assembly, and can meet the use requirements of general cylindrical roller bearings. However, limited by the structure, the B-shaped cage cannot increase the number of rollers, which will affect the bearing capacity and service life of the bearing; And the mold structure is complex and the manufacturing is cumbersome. When the dimensional accuracy requirements are high, it can not meet the service conditions. It was nearly eliminated as early as the 1990s. Therefore, it is not included in the type of cylindrical roller stamped cages in JB / T 10337-2002 Technical Conditions for Stamped Cages of Rolling Bearing Parts. Although some of these cages are still produced and used, they are not the mainstream.

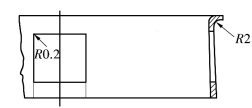

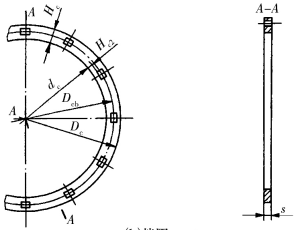

Fig.1 Z - shaped cage

2.2 Cylindrical cage

The cylindrical cage is the optimized structure of the B-shaped cage. Its window hole is changed into a forming slope instead of the B-shaped claw. During assembly, the cage beam is pressed inward through the assembly die to lock the roller. The utility model has the advantages of simpler structure, good stamped processability, higher manufacturing accuracy and easy assembly.

Fig.2 Cylinder - shaped cage

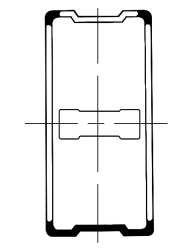

2.3 Grooved and double end cap combined cage

In order to overcome the shortcomings of B-shaped cage, groove cage and double end cap combined cage have appeared. These two kinds of structural cages are the most widely used cylindrical roller bearing stamped cages at present. Only these two types are listed in the new GB / T 28268-2012.

Fig. 3 Groove - shaped cage

The grooved cage can maximize the length and number of rollers, so as to improve the bearing capacity and service life of the bearing. However, the structure and manufacturing process of groove cage are complex, and the processing is difficult, especially the forming of assembly lock point is difficult; During assembly, not only the appropriate assembly die is required, but also the inner flanging and locking point are easy to interfere with the roller (pinch roller). Almost all of these problems of groove cage are related to mold and tooling. Due to the problems of mold structure and accuracy, the geometric accuracy of products is poor, and various problems appear in use. At present, grooved cages are widely used in cylindrical roller bearings abroad, but they encounter bottlenecks and are limited in use in China.

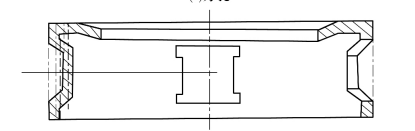

The combined cage (classified as pressed cage because the retaining ring and pillar are stamped and cold drawn parts) is composed of pillar and retaining ring riveted, and the structure is shown in Figure 4. Roller and cage components can be formed. The cage is convenient for oil storage and lubrication and has high production efficiency. However, the structural strength is affected by the strut, and the friction between the strut and the roller is large, so it is not suitable for high-speed working conditions.

Fig. 4 Double closing ring combination cage

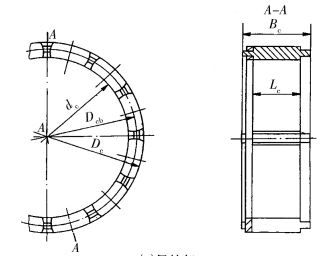

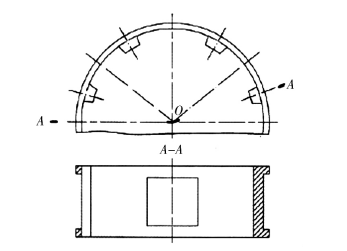

2.4 M-shaped cage

M-shaped cage (Fig. 5) is developed from the structure of K-shaped cage of needle roller bearing. Its advantages are: the contact area between roller and cage is small, and the friction torque of bearing is reduced; At the same time, the roller has sufficient clearance with the cage in the axial direction, which is conducive to maintaining the circulation of roller and lubricant. Compared with the groove and B-shaped structure, the structure of M-shaped cage is simpler. The special surface strengthening treatment can make the cage stronger. It is suitable for occasions with high speed, large centrifugal force and vibration and poor lubrication.

Fig. 5 M - shaped cage

2.5 M-shaped and cylindrical cages with end lock

The M-shaped cage with end lock (Fig. 6) has various advantages of the original M-shaped cage. More importantly, it can form an assembly with the roller alone. During assembly, the recess of the roller end face can be pushed into the locking point, which is more convenient for assembly.

Fig. 6 M - shaped cage with end lock

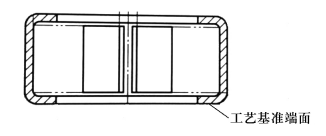

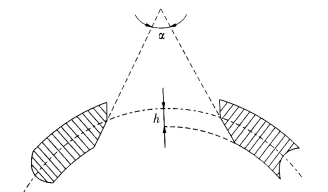

The structure of a cylindrical cage with end lock is shown in Figure 7a. The cage is a new type of structure. The pocket hole is a rounded rectangle, the two sides corresponding to the pocket hole along the circumferential direction are inclined planes, and the opening distance between the two inclined planes gradually increases along the radial direction of the cage; The included angle formed by the extension line of the pocket corresponding to the two inclined planes α=28 °; The vertical distance h between the outer edge of the inclined plane and the inner circumferential surface of the cage is 1.5 mm; Arc or right angle notches are respectively arranged on both sides of the pocket hole.

The cage is provided with a notch in the pocket, so that the cage is easy to plastic deformation and produce pressure points during assembly, so as to lock the end face of the roller and make assembly easier; It can realize the self-locking function of B-shaped and M-shaped cages, so as to lengthen the roller, increase the diameter and increase the bearing capacity; Compared with the original cylindrical cage, it is easier to ensure geometric accuracy and reduce bearing noise.

2.6 Summary

The structure of stamped cage of cylindrical roller bearing changes with the continuous development of stamped die and material technology. At present, all kinds of stamped cages are applied in China, and there is no obvious substitution trend. It is gradually moving towards higher bearing capacity and service life (accommodating longer and larger diameter rollers), simple and practical structure (easier to ensure geometric accuracy), good processing technology (easier to make dies), The direction of convenient assembly (simple assembly die or no need for assembly die).

Fig. 7 Cylinder - shaped cage with end lock

3. Development trend of stamped cage

At present, the development of stamped cage technology of cylindrical roller bearing in China is relatively slow, mainly for several reasons: 1) the bearing design is relatively backward, and the cage is not paid enough attention to. It is considered that the accuracy of cage as an auxiliary part is too different from that of bearing, which can be used without problems, and the structural type and manufacturing method of cage have not been deeply studied; 2) The market does not know enough about stamped cages and is not recognized by users. Under the same use conditions, more expensive copper cages can be used instead of steel cages; 3) Lack of research talents and research depth. At present, most improved and new cages are the surveying and mapping of foreign products, and their specific connotation has not been studied deeply; 4) Domestic stamped equipment and dies are relatively backward, resulting in poor geometric accuracy and performance problems.

Although there are some problems in the development of cylindrical roller bearing stamped cage in China, it still has an irreplaceable position in the performance of high speed, heavy load, long life and low noise. For example, the inner suspension beam brass cage of cylindrical roller bearing for a compressor has no problem when the rotating speed is less than 4000 r / min (the rotating speed of general compressor support bearing), but when the rotating speed increases to more than 5000 r / min, the cage fracture fault will occur. The improvement of M-shaped stamped cage solves the high-speed problem of cylindrical roller bearing.

With the popularization and application of high-speed precision blanking, automatic welding and shaping technology, the stamped cage of cylindrical roller bearing has the trend of developing to large-size section and gradually replacing solid copper cage. The development direction of stamped cage technology mainly lies in structural innovation, and the development of new cage structure also depends on the improvement of cage material and process equipment.

Fig. 8 Brass cage with inner hanging beam

Fig. 9 Improved M - shaped cage

The stamped cage of cylindrical roller bearing is widely used abroad and has a trend of increasing gradually. The main breakthrough point is the innovation of structure and the improvement of machining accuracy. It is believed that the domestic situation will change with the progress of technology and the adjustment of market.

More about WSW Cylindrical Roller Bearing:

The roller of cylindrical roller bearing is in line contact with the raceway and has large radial bearing capacity. It is suitable for bearing heavy load and impact load. Low friction coefficient, suitable for high speed, and the limit speed is close to the deep groove ball bearing. N-type and nu type can move axially, can adapt to the change of relative position between shaft and shell caused by thermal expansion or installation error, and can be used as free end support. The inner ring or outer ring can be separated for easy installation and disassembly. The processing requirements for the shaft and seat hole are high. After the bearing is installed, the relative deviation of the axis of the inner and outer rings shall be strictly controlled to avoid contact stress concentration. Double row cylindrical roller bearing with 1:12 taper in inner hole has adjustable radial clearance and high radial stiffness, which is suitable for machine tool spindle.

WBM are professional taper roller manufacturers and suppliers in China, with bulk high-quality products in stock. If you are going to buy a customized taper roller at a competitive price, welcome to get a quotation from the WBM factory. In line with the business philosophy of pursuing excellence, continuous improvement and common prosperity, the ball header, solid steel balls, roller header produced from WBM is absolutely high-quality and inexpensive.